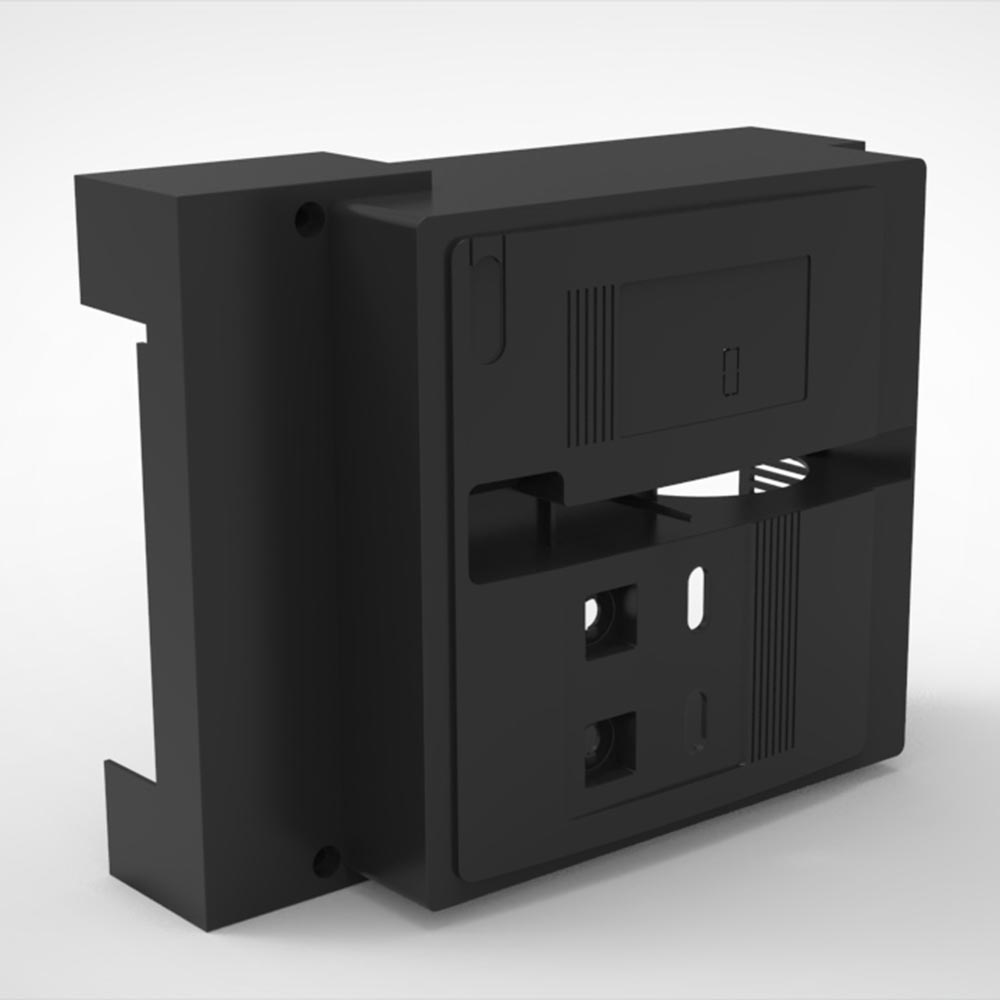

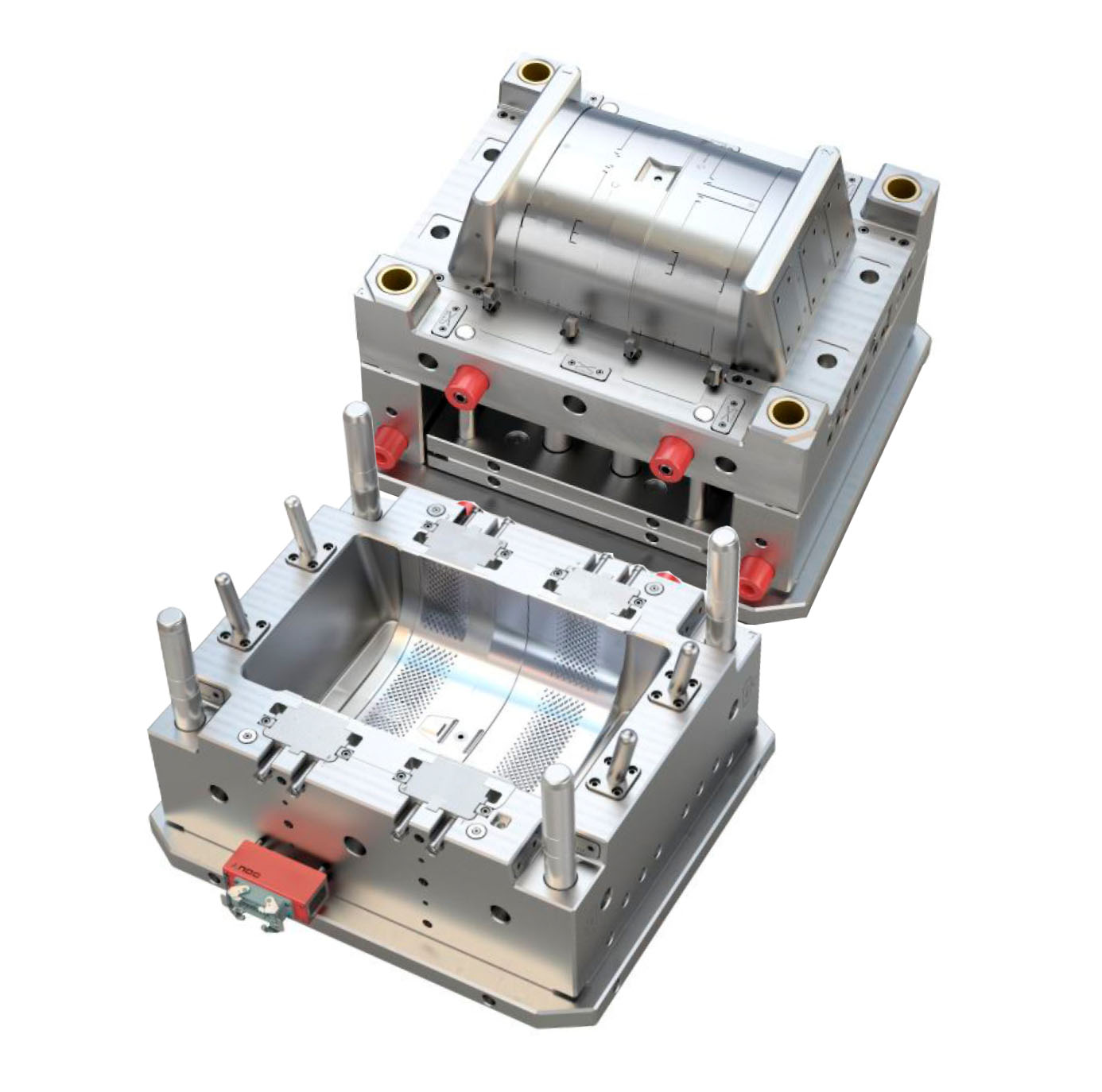

Electricity meter box parts mold

Meter box accessory moldsare a general term for a series of injection molds used to produce various components of power distribution meter boxes. These molds belong tolarge or medium-sized injection molds, and typically require high precision, high strength, and good appearance quality. Because their products (meter box accessories) are directly related to electrical safety, outdoor durability, and ease of installation, there are very high requirements for the design, materials, and manufacturing process of the molds.

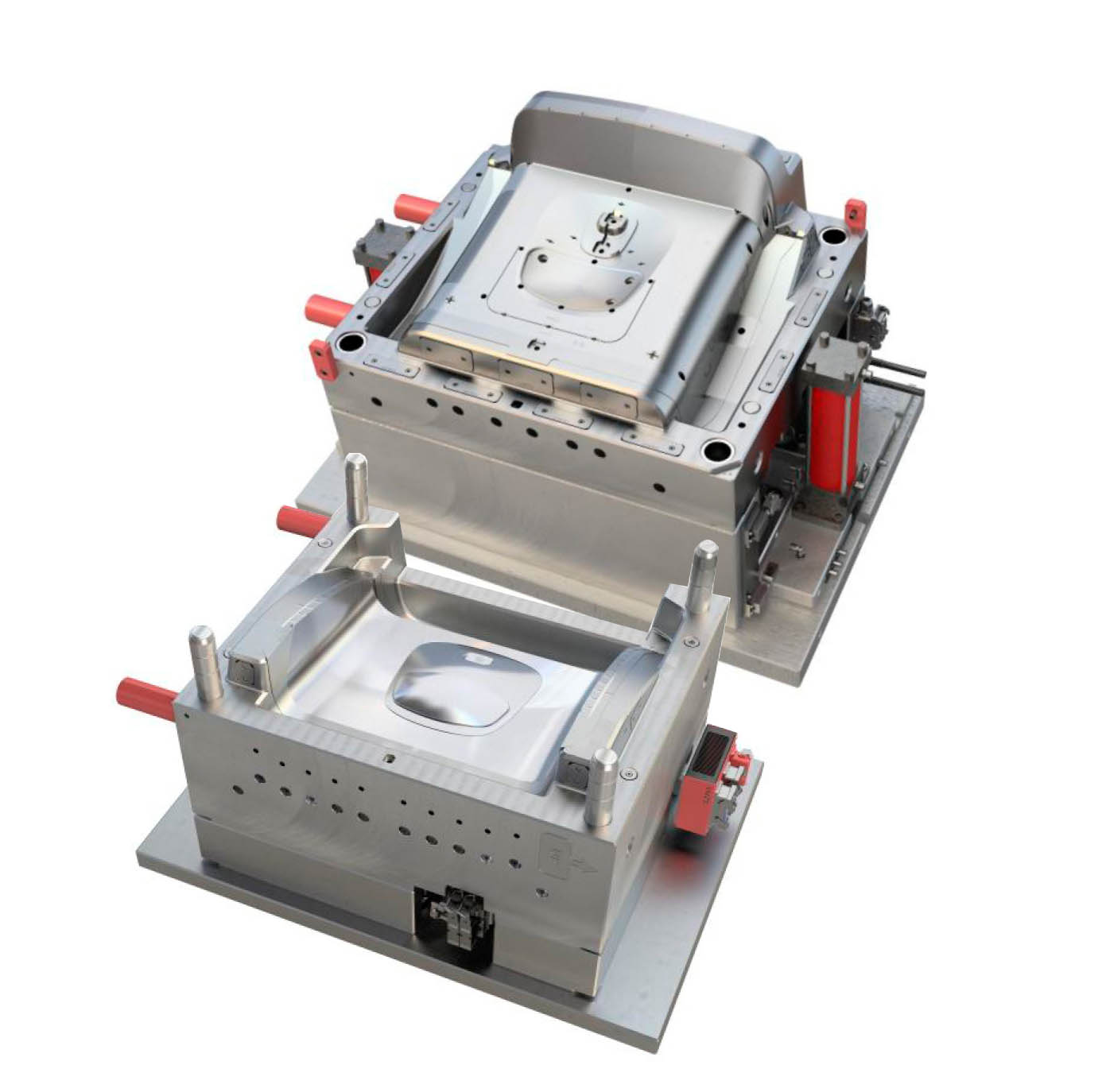

Large-scale and Heavy-duty: The box mold itself is huge in size and weight, often reaching several tons or even tens of tons.

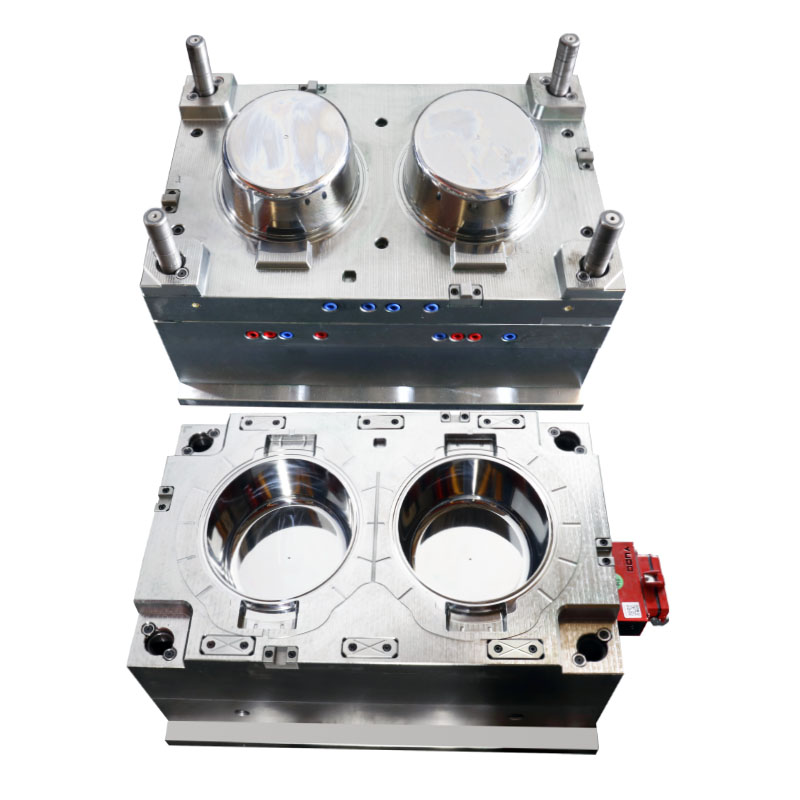

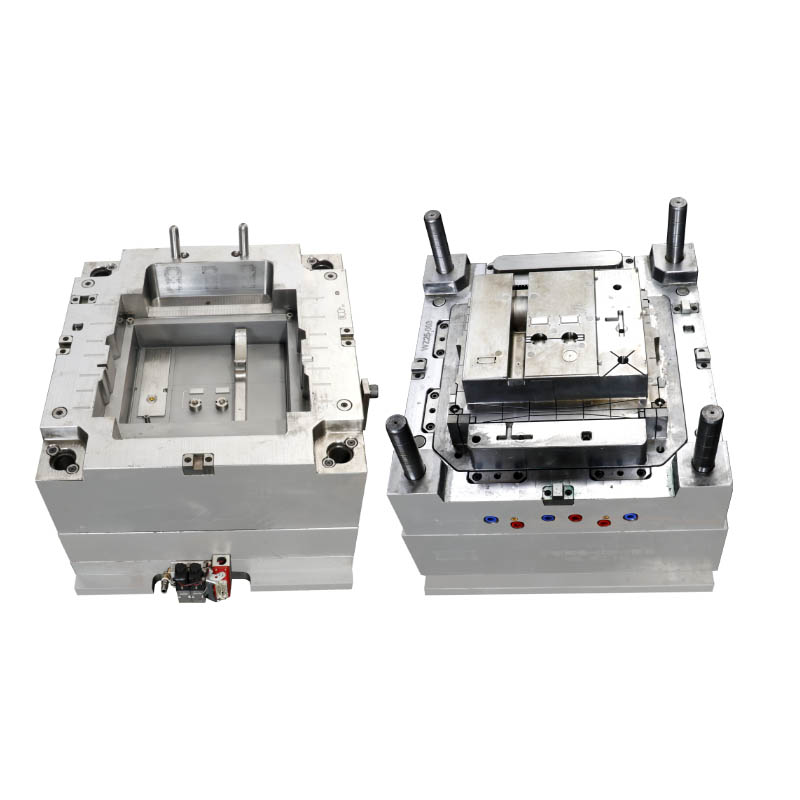

Large-scale and Heavy-duty. High Rigidity Requirements: Under the enormous clamping force of the injection molding machine, the mold must possess extremely high rigidity. The mold plate must be thick, and there must be numerous and rationally arranged support columns to prevent deformation. Strict Material Requirements: The core and cavity mainly use pre-hardened mold steel (such as P20, 718H). For high-volume molds, steels with higher quenching hardness (such as S136, H13) are used and heat-treated to ensure long-term wear resistance and corrosion resistance. High-strength wear-resistant steel is also used for moving parts such as sliders and angled tops. Precision machining and collaboration: Requires the collaborative work of multiple equipment such as large CNC machines, deep hole drills (for cooling water channels), large EDM machines, and precision wire cutting machines. The processing cycle is long and the technical requirements are high. Lifespan and Maintenance: The design lifespan is typically over one million cycles. The mold features a modular design, facilitating the replacement and maintenance of vulnerable parts (such as ejector pins, slide plates, and pressure plates).

1. Core Functions and Target Products

These molds are used to manufacture all the plastic components of a complete meter box, mainly including:

Box Body and Cover: The largest components, forming the main structure of the meter box.

Guide Rails: Metal or plastic brackets used to install components such as electricity meters and circuit breakers. Plastic guide rails are usually produced by injection molding.

Terminal Block/Bracket: Structural components for fixing wiring terminals.

Terminal Block/Bracket. Small functional components such as sealing ring mounting groove cover plate, cable outlet plug, locking mechanism, and mounting ear. 2. Mold Structure and Components (for typical box/cover molds) Electric meter box accessory molds, especially box molds, have complex structures and represent a concentrated embodiment of technology and value. a. Molding System Cavity: Forms the outer surface of the component, requiring a high degree of smoothness. It is usually treated with mirror polishing or texturing to achieve an aesthetically pleasing or matte outer casing surface. Core: Forms the inner surface of the component. It has a complex structure, containing numerous reinforcing ribs, clips, screw posts, functional mounting positions, etc. This is the most challenging and crucial aspect of mold design. b. Core Pulling System This is the most complex part of the meter box mold. Because the box body often has snap-fit slots, cable outlet holes, mounting positions, etc., it cannot be directly molded; a complex side-pulling mechanism must be used. Slider: Used to handle holes and slots on the sides of the box body. Large box molds may have as many as 8-10 sliders, which are pulled out sequentially from different directions. Angled Top: Used to handle undercuts inside the box body that are inconsistent with the mold opening direction, such as internal snap-fits. Hydraulic/Pneumatic Cylinders: For sliders with long core-pulling distances or requiring high force, hydraulic cylinders are used for direct drive. c. Hot Runner System To ensure the aesthetic appearance of large box surfaces, reduce gate marks, shorten molding cycles, and save raw materials, electric meter box molds commonly employ hot runner systems, or even very complex multi-point hot nozzle sequence valve control systems, to ensure that the melt can fill the large cavity evenly and quickly, and reduce the impact of weld marks. d. Cooling System The cooling effect directly determines production efficiency and the degree of product deformation. The cooling system of the meter box mold is extremely complex, employing multi-layered, multi-loop cooling water channels, and extensively using efficient cooling methods such as water wells, partitioned water jackets, and spiral water troughs, especially in areas where heat is concentrated, such as the core and slider, to ensure uniform and efficient cooling. e. Ejection System A combination of multiple ejection methods, including ejector pins, ejector sleeves (ejector tubes), and push plates, is employed to ensure that large and deep-cavity products can be ejected smoothly and without deformation. f. Venting System Sufficient venting grooves are provided at the parting surface, slide mating surface, and ejector pin positions to prevent defects such as scorching and insufficient filling caused by trapped air. This is especially important for large, flat products.

FAQS

A: We are a specialized manufacturer of precision molds, with a primary focus on Cold Fan (Air Cooler) Molds and a comprehensive range of Home Appliance Molds. This includes molds for components in refrigerators, air conditioners, washing machines, and small kitchen appliances.

A: Absolutely. We provide an end-to-end solution, from initial design and engineering (DFM), 3D modeling, and precision machining to mold trials, sampling, and final production support. We are your one-stop shop for a complete mold project.

A: We ensure quality through a multi-step process: using high-grade mold steels, operating state-of-the-art CNC machining centers, and implementing a rigorous Quality Control (QC) system. Every mold undergoes precise measurement and a thorough trial process to verify its performance and the quality of the parts it produces.

A: Yes, we highly recommend and provide DFM analysis at the beginning of every project. Our engineering team will review your part design to optimize it for manufacturability, suggesting improvements for moldability, cost-efficiency, and part performance.

A: Lead times vary depending on the mold's complexity and size. For a standard cold fan or home appliance mold, the typical lead time ranges from 4 to 8 weeks. We will provide a detailed project timeline with a specific completion date after reviewing your technical requirements.

A: Of course. We always produce and provide initial sample parts (T1) from the new mold for your approval. This allows you to verify dimensions, appearance, and function before we proceed to mass production.

A: Our molds are designed to process various common plastics used in appliances, including ABS, PP, PS, PC, and PA (Nylon). We select the appropriate mold steel and design the mold structure based on your specific material choice.

A: We offer comprehensive after-sales support. This includes providing detailed mold maintenance guidelines and offering repair and modification services to ensure your mold maintains peak performance and a long service life, maximizing your return on investment.

A: Our key differentiator is our dual specialization. We are not just general mold makers; we have deep, specific expertise in both the highly technical Cold Fan category and the broad Home Appliance market. This focus allows us to provide superior engineering solutions and value for our clients in these sectors.

A: We take IP protection extremely seriously. We are willing to sign a strict Non-Disclosure Agreement (NDA) before any project discussion. All your designs, drawings, and data are treated with the utmost confidentiality and are never shared with any third party.

Standard Process for Ordering Injection Molds:

| Phase | Stage | Key Activities / Deliverables | Responsible Party | Purpose & Notes |

|---|---|---|---|---|

| Phase 1: Project Initiation & Feasibility | 1. RFQ (Request for Quotation) | • Provide detailed product design (3D CAD, 2D drawings). • Specify requirements: material, annual volume, target part cost, lead time. | Customer | Establishes the project baseline and allows the mold supplier to provide an accurate quotation. |

| 2. Design for Manufacturability (DFM) Review | • Mold supplier analyzes the product design for moldability. • Provides DFM report with suggestions on draft angles, wall thickness, gate locations, shrinkage, etc. | Mold Supplier (with Customer approval) | Critical for avoiding costly mold modifications later. Ensures the part is optimized for injection molding. | |

| 3. Quotation & Commercial Agreement | • Submit a detailed quotation covering mold cost, payment terms, and project timeline. • Negotiate and sign a purchase order (PO) and/or contract. | Mold Supplier & Customer | Formalizes the commercial agreement and project scope. | |

| Phase 2: Engineering & Design | 4. Mold Design Finalization | • Create detailed mold flow analysis. • Finalize mold design (2D layout, 3D model) including: cavity/core, slider/lifter mechanisms, cooling system, ejection system. • Customer approves final mold design. | Mold Supplier (with Customer approval) | The mold design is the blueprint for manufacturing. Approval at this stage is crucial. |

| 5. Material & Component Sourcing | • Procure approved mold base, steel (e.g., P20, H13, Stainless for corrosive materials), and standard components (hot runners, ejector pins, etc.). | Mold Supplier | Using quality materials is essential for mold life and performance, especially for high-volume家电 (home appliances). | |

| Phase 3: Mold Manufacturing | 6. Machining & Fabrication | • CNC machining of cavity and core. • EDM, wire cutting, grinding, and polishing. • Fabrication of all mold components. | Mold Supplier | The physical creation of the mold. Regular progress updates (e.g., photos) are often provided. |

| 7. Fitting & Assembly | • Assemble all machined components into the mold base. • Check for proper fit and function of all moving parts (sliders, lifters, ejection). | Mold Supplier | Ensures the mechanical integrity of the mold before the first trial. | |

| Phase 4: Sampling & Validation | 8. T1 (First Trial) & Initial Sample Report (ISIR) | • Conduct the first mold trial on an injection molding machine. • Measure and inspect T1 samples. • Provide a detailed T1 trial report with samples, pictures, and data (dimensions, short shots, etc.). | Mold Supplier | The first physical verification of the mold's performance. Identifies initial issues. |

| 9. Sample Evaluation & Engineering Changes | • Customer evaluates T1 samples for dimensions, appearance, and function. • Provide formal feedback for any required mold modifications (ECN - Engineering Change Notice). | Customer | Customer's turn to validate the part against their design and quality standards. | |

| 10. Mold Modification & Further Trials (T2, T3...) | • Implement approved ECNs. • Conduct subsequent trials (T2, T3) until samples meet all approval criteria. • Submit PPAP (Production Part Approval Process) samples if required. | Mold Supplier (with Customer feedback) | Iterative process to refine the mold until it produces acceptable parts. | |

| Phase 5: Final Approval & Delivery | 11. Final Sample Approval | • Customer issues a formal Sample Approval Sheet or sign-off. | Customer | Official confirmation that the mold produces parts to specification. |

| 12. Mold Finish & Documentation | • Apply final surface finishes (e.g., texture, polish). • Prepare and deliver final documentation: mold design drawings, maintenance manual, mold certificate. | Mold Supplier | Prepares the mold for production and provides necessary documentation for its future maintenance. | |

| 13. Shipment & Delivery | • Arrange secure packaging and shipment of the approved mold to the production facility. • Settle final payment as per the agreement. | Mold Supplier & Customer | Transfer of ownership and physical asset. | |

| Phase 6: Post-Delivery Support | 14. Production Support & Warranty | • Provide technical support during production ramp-up. • Honor the agreed warranty period for workmanship and materials. | Mold Supplier | Ensures a smooth transition to mass production and protects the customer's investment. |