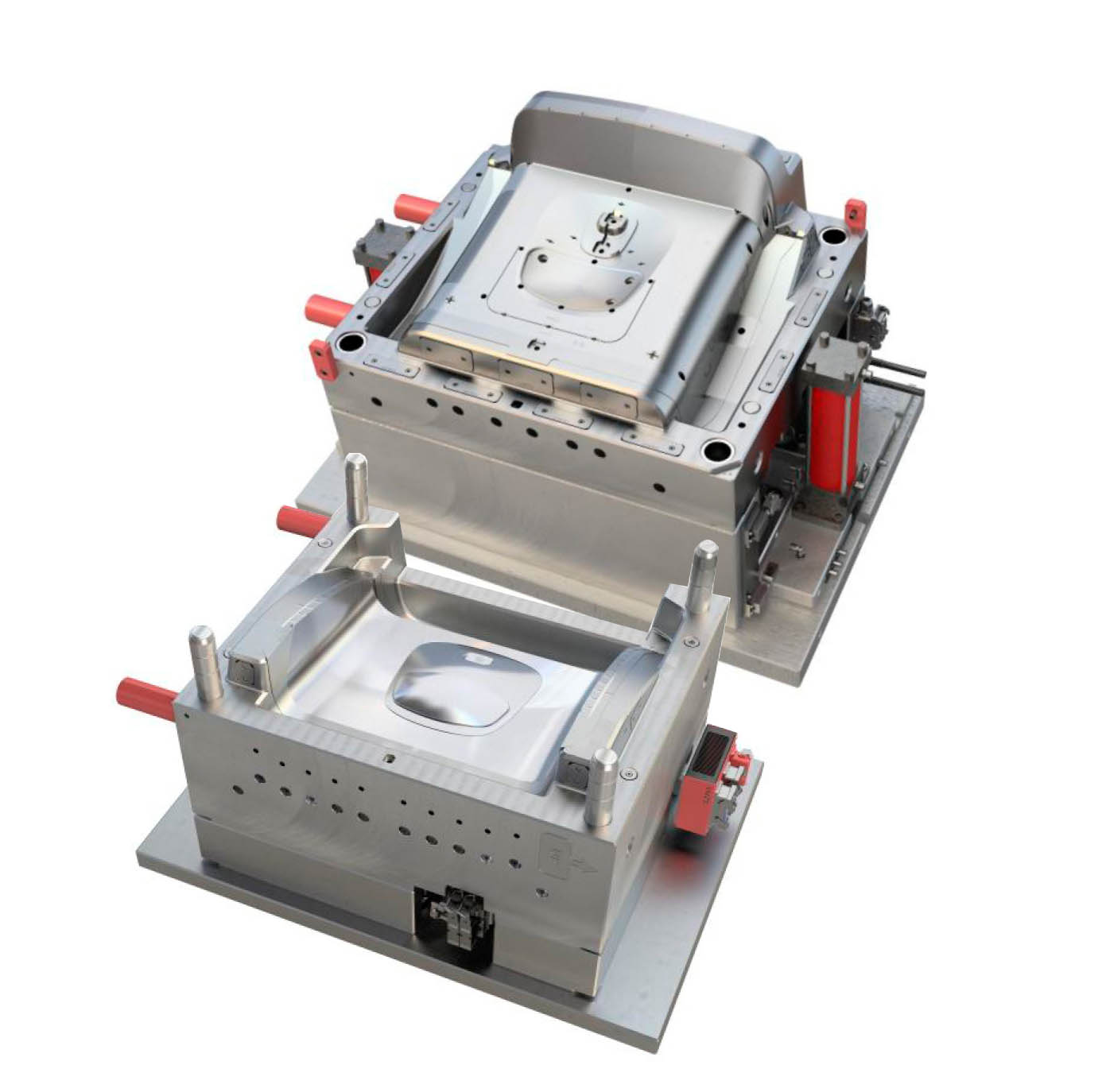

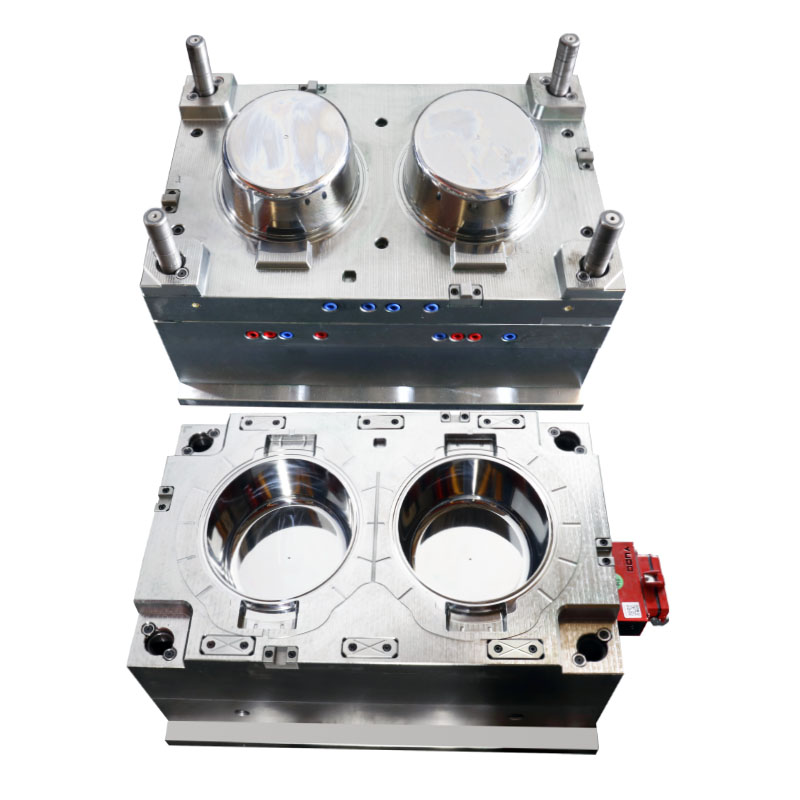

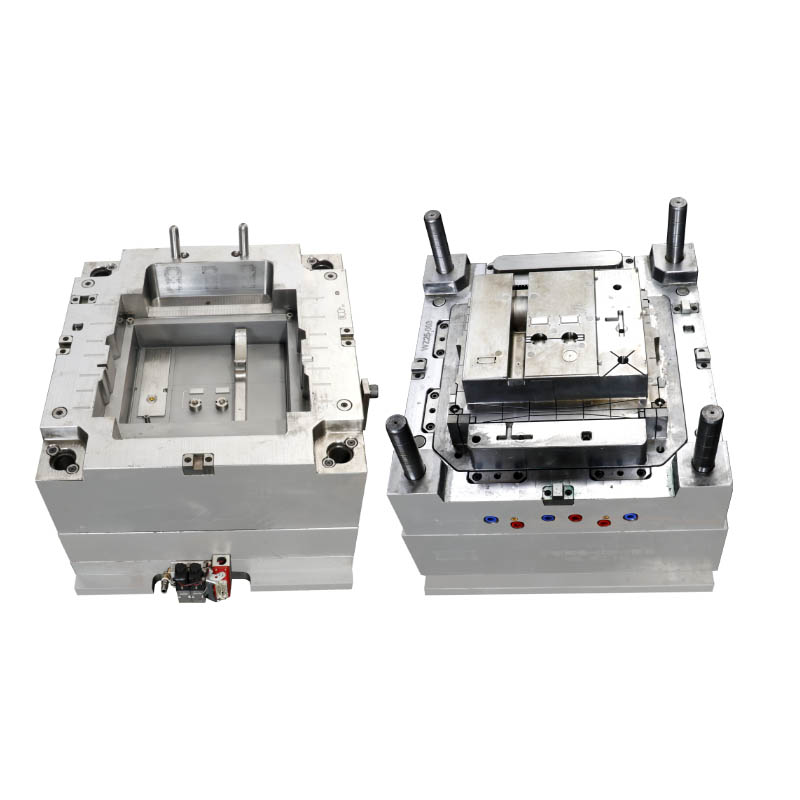

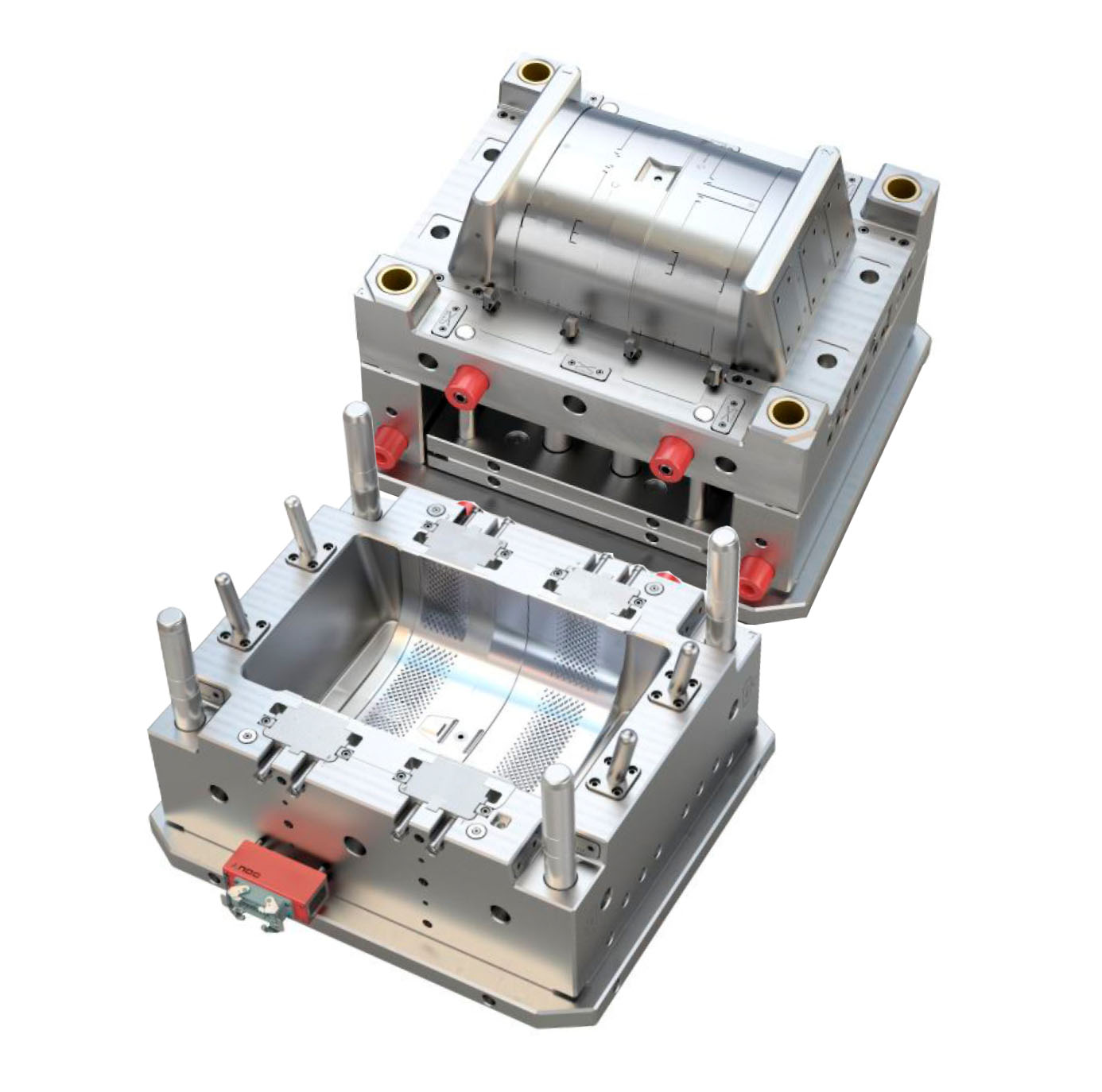

Controller accessories mold

High-transmittance display window molds: Ensure clear, distortion-free images.

Light guide and light diffuser molds: Provide uniform light guidance, eliminating dark areas and bright spots.

Transparent touch panel and housing molds: Strive for a crystal-clear appearance and durability.

Internal precision structural molds: Ensure precise assembly of transparent components with other controller components.

To meet both the precision requirements of controller components and the optical requirements of transparent parts, our molds offer the following outstanding features:

Ultimate Optical Cavity Treatment

Diamond-grade polishing or ultra-high-precision optical coating processes are used to achieve optical mirror-like finishes in the mold cavity, ensuring a light transmittance of ≥92% for the molded product, resulting in a crystal-clear visual effect.

Zero-Defect Molding Technology

Mold flow analysis accurately predicts and eliminates flow marks, weld lines, bubbles, and other defects that may affect optical performance and appearance, particularly at the gate, achieving "scratch-free" injection molding.

Ultra-Stable Temperature Control System

A balanced and efficient cooling circuit ensures a highly uniform temperature field in the mold cavity, fundamentally preventing defects such as ripples and sink marks caused by uneven cooling, and ensuring excellent dimensional stability and optical consistency.

Protective Automated Production Design

The mold structure design focuses on achieving "zero-contact" or "soft-contact" protection for the transparent surface during ejection and demolding. Automated processes prevent human scratches, ensuring product yield from the manufacturing end. III. Our Core Manufacturing Advantages

Advantage 1: Integrated Optical and Structural Integration

We not only pursue ultimate transparency, but also meticulously integrate invisible internal features such as clips and positioning pins into the design. This ensures both perfect optical performance and easy and secure assembly.

Advantage 2: In-depth Understanding of Material Properties

We are familiar with the viscosity, refractive index, and processing window of optical plastics such as PC, PMMA, and transparent ABS. We can precisely set process parameters based on the specific material properties to maximize their potential.

Advantage 3: Dust-Free Production and Full-Process Cleanliness Control

From mold manufacturing, assembly, and mold trialing, we implement strict dust-free management to prevent dust and oil contamination from the mold cavity and the finished product, ensuring that every transparent component is pristine and flawless.

FAQS

A: We are a specialized manufacturer of precision molds, with a primary focus on Cold Fan (Air Cooler) Molds and a comprehensive range of Home Appliance Molds. This includes molds for components in refrigerators, air conditioners, washing machines, and small kitchen appliances.

A: Absolutely. We provide an end-to-end solution, from initial design and engineering (DFM), 3D modeling, and precision machining to mold trials, sampling, and final production support. We are your one-stop shop for a complete mold project.

A: We ensure quality through a multi-step process: using high-grade mold steels, operating state-of-the-art CNC machining centers, and implementing a rigorous Quality Control (QC) system. Every mold undergoes precise measurement and a thorough trial process to verify its performance and the quality of the parts it produces.

A: Yes, we highly recommend and provide DFM analysis at the beginning of every project. Our engineering team will review your part design to optimize it for manufacturability, suggesting improvements for moldability, cost-efficiency, and part performance.

A: Lead times vary depending on the mold's complexity and size. For a standard cold fan or home appliance mold, the typical lead time ranges from 4 to 8 weeks. We will provide a detailed project timeline with a specific completion date after reviewing your technical requirements.

A: Of course. We always produce and provide initial sample parts (T1) from the new mold for your approval. This allows you to verify dimensions, appearance, and function before we proceed to mass production.

A: Our molds are designed to process various common plastics used in appliances, including ABS, PP, PS, PC, and PA (Nylon). We select the appropriate mold steel and design the mold structure based on your specific material choice.

A: We offer comprehensive after-sales support. This includes providing detailed mold maintenance guidelines and offering repair and modification services to ensure your mold maintains peak performance and a long service life, maximizing your return on investment.

A: Our key differentiator is our dual specialization. We are not just general mold makers; we have deep, specific expertise in both the highly technical Cold Fan category and the broad Home Appliance market. This focus allows us to provide superior engineering solutions and value for our clients in these sectors.

A: We take IP protection extremely seriously. We are willing to sign a strict Non-Disclosure Agreement (NDA) before any project discussion. All your designs, drawings, and data are treated with the utmost confidentiality and are never shared with any third party.

Standard Process for Ordering Injection Molds:

| Phase | Stage | Key Activities / Deliverables | Responsible Party | Purpose & Notes |

|---|---|---|---|---|

| Phase 1: Project Initiation & Feasibility | 1. RFQ (Request for Quotation) | • Provide detailed product design (3D CAD, 2D drawings). • Specify requirements: material, annual volume, target part cost, lead time. | Customer | Establishes the project baseline and allows the mold supplier to provide an accurate quotation. |

| 2. Design for Manufacturability (DFM) Review | • Mold supplier analyzes the product design for moldability. • Provides DFM report with suggestions on draft angles, wall thickness, gate locations, shrinkage, etc. | Mold Supplier (with Customer approval) | Critical for avoiding costly mold modifications later. Ensures the part is optimized for injection molding. | |

| 3. Quotation & Commercial Agreement | • Submit a detailed quotation covering mold cost, payment terms, and project timeline. • Negotiate and sign a purchase order (PO) and/or contract. | Mold Supplier & Customer | Formalizes the commercial agreement and project scope. | |

| Phase 2: Engineering & Design | 4. Mold Design Finalization | • Create detailed mold flow analysis. • Finalize mold design (2D layout, 3D model) including: cavity/core, slider/lifter mechanisms, cooling system, ejection system. • Customer approves final mold design. | Mold Supplier (with Customer approval) | The mold design is the blueprint for manufacturing. Approval at this stage is crucial. |

| 5. Material & Component Sourcing | • Procure approved mold base, steel (e.g., P20, H13, Stainless for corrosive materials), and standard components (hot runners, ejector pins, etc.). | Mold Supplier | Using quality materials is essential for mold life and performance, especially for high-volume家电 (home appliances). | |

| Phase 3: Mold Manufacturing | 6. Machining & Fabrication | • CNC machining of cavity and core. • EDM, wire cutting, grinding, and polishing. • Fabrication of all mold components. | Mold Supplier | The physical creation of the mold. Regular progress updates (e.g., photos) are often provided. |

| 7. Fitting & Assembly | • Assemble all machined components into the mold base. • Check for proper fit and function of all moving parts (sliders, lifters, ejection). | Mold Supplier | Ensures the mechanical integrity of the mold before the first trial. | |

| Phase 4: Sampling & Validation | 8. T1 (First Trial) & Initial Sample Report (ISIR) | • Conduct the first mold trial on an injection molding machine. • Measure and inspect T1 samples. • Provide a detailed T1 trial report with samples, pictures, and data (dimensions, short shots, etc.). | Mold Supplier | The first physical verification of the mold's performance. Identifies initial issues. |

| 9. Sample Evaluation & Engineering Changes | • Customer evaluates T1 samples for dimensions, appearance, and function. • Provide formal feedback for any required mold modifications (ECN - Engineering Change Notice). | Customer | Customer's turn to validate the part against their design and quality standards. | |

| 10. Mold Modification & Further Trials (T2, T3...) | • Implement approved ECNs. • Conduct subsequent trials (T2, T3) until samples meet all approval criteria. • Submit PPAP (Production Part Approval Process) samples if required. | Mold Supplier (with Customer feedback) | Iterative process to refine the mold until it produces acceptable parts. | |

| Phase 5: Final Approval & Delivery | 11. Final Sample Approval | • Customer issues a formal Sample Approval Sheet or sign-off. | Customer | Official confirmation that the mold produces parts to specification. |

| 12. Mold Finish & Documentation | • Apply final surface finishes (e.g., texture, polish). • Prepare and deliver final documentation: mold design drawings, maintenance manual, mold certificate. | Mold Supplier | Prepares the mold for production and provides necessary documentation for its future maintenance. | |

| 13. Shipment & Delivery | • Arrange secure packaging and shipment of the approved mold to the production facility. • Settle final payment as per the agreement. | Mold Supplier & Customer | Transfer of ownership and physical asset. | |

| Phase 6: Post-Delivery Support | 14. Production Support & Warranty | • Provide technical support during production ramp-up. • Honor the agreed warranty period for workmanship and materials. | Mold Supplier | Ensures a smooth transition to mass production and protects the customer's investment. |