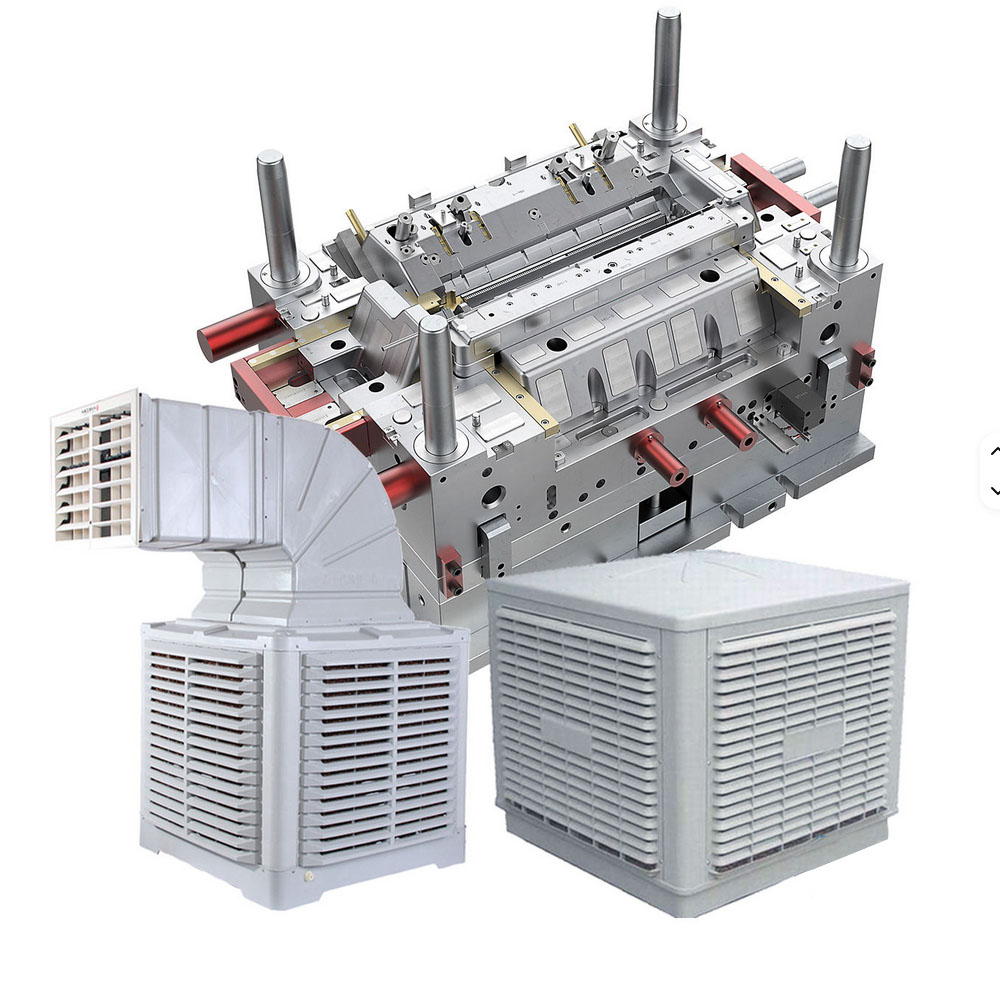

Portable evaporative cooling fan mold

I. Product Insights and Mold Description

Outdoor portable air coolers integrate air supply, water circulation cooling, battery power, and portability, requiring mold manufacturing far beyond the capabilities of ordinary household appliances. We offer mold solutions covering all of their core components:

High-efficiency turbine duct system molds: These molds are used to manufacture the core centrifugal impeller and vortex casing, which are key to achieving high air volume, low noise, and long air delivery distances.

Integrated housing and structural component molds: These molds include front and rear covers, water tanks, and handles, focusing on aesthetics, assembly precision, and lightweight design.

Precision cooling system molds: These molds provide efficient cooling ducts or fin structures for the built-in lithium battery and control system.

Multi-function panel and button molds: These molds meet the waterproof and dustproof requirements typically encountered in outdoor applications.

Here is what sets us apart:

1. Unmatched Specialization & Domain Expertise

Feature: We focus 100% on molds for the air cooler industry.

Your Advantage: You benefit from our profound understanding of airflow dynamics, water management, material selection (e.g., PP, ABS, flame-retardant grades), and regulatory standards. This means proactive design advice and molds built for optimal performance from the start.

2. Performance-Oriented Engineering

Feature: Advanced Mold Flow Analysis and CAE simulation are standard for every project.

Your Advantage: We predict and eliminate potential defects like warping and sink marks. We optimize cooling channel design to significantly reduce cycle times, directly lowering your production costs and increasing your manufacturing throughput.

3. Mastery of Complex Mechanisms for Superior Parts

Feature: Expertise in sophisticated mold technologies including hot runners, sequential valve gating, sliders, and lifters.

Your Advantage: We can produce complex, high-precision components—such as oscillating grilles, integrated snap-fits, and leak-proof water tanks—with impeccable quality and high production efficiency.

4. Aesthetic Excellence as a Standard

Feature: Dedicated capabilities for achieving Class-A surfaces, high-gloss polishing, and precise texturing (VDI 3400).

Your Advantage: Your air coolers will have the premium look and feel that commands attention in the market. We ensure cosmetically perfect parts on all visible surfaces, enhancing your brand's reputation for quality.

5. Built for Durability and High-Volume Production

Feature: Use of premium mold steels (H13, S136) and robust construction techniques.

Your Advantage: Our molds are engineered for longevity and stability over millions of cycles. This minimizes production downtime for maintenance and ensures consistent part quality throughout the entire product life cycle, protecting your investment.

6. Seamless Partnership & Project Management

Feature: An end-to-end, collaborative service model from DFM to mass production support.

Your Advantage: Experience a transparent, efficient process with clear communication. We act as an extension of your team, ensuring a smooth journey from concept to mass production and a faster launch for your products.

模具设计与制造特点

为应对户外使用的挑战,我们的模具具备以下突出特点:

结构高度集成化

采用模内组装和滑块抽芯等复杂结构,在单次注塑中成型卡扣、装配位等复杂特征,减少后续工序,提升生产效率和装配精度。

面向轻量化与强度的设计

通过CAE分析进行肉厚优化,在保证结构强度的前提下,最大限度减少材料用量,减轻产品重量,并防止缩水变形。

针对受力部位进行针对性加强筋设计。

卓越的冷却与散热效能

风道与散热部件模具型腔需达到镜面或细纹级别,减少风阻,提升空气流动效率,直接提升整机性能和电池续航。

满足户外环境的耐用性

模具钢材选用耐磨、防锈的优质材料,确保模具在长期生产中的稳定性。

成品部件具备优异的抗UV、抗冲击性能,满足户外频繁使用的苛刻要求。

三、 我们的核心制造优势

优势一:跨学科整合能力

我们精通空气动力学、塑料工程与电子散热,能将功能性需求(如风效、散热)精准转化为可制造的模具方案,而非简单的结构复制。优势二、微精度控制

对风轮动平衡、风道间隙、密封面等关键部位实行微米级精度控制,确保组装后整机运行平稳、噪音低、无异响。优势三、快速迭代与成本优化

凭借丰富的经验,我们在设计阶段即可预见并规避生产风险,提供DFM(可制造性设计)报告,帮助客户优化产品设计,缩短开发周期,并采用模块化模具设计理念,有效降低开模成本。

FAQS

A: We are a specialized manufacturer of precision molds, with a primary focus on Cold Fan (Air Cooler) Molds and a comprehensive range of Home Appliance Molds. This includes molds for components in refrigerators, air conditioners, washing machines, and small kitchen appliances.

A: Absolutely. We provide an end-to-end solution, from initial design and engineering (DFM), 3D modeling, and precision machining to mold trials, sampling, and final production support. We are your one-stop shop for a complete mold project.

A: We ensure quality through a multi-step process: using high-grade mold steels, operating state-of-the-art CNC machining centers, and implementing a rigorous Quality Control (QC) system. Every mold undergoes precise measurement and a thorough trial process to verify its performance and the quality of the parts it produces.

A: Yes, we highly recommend and provide DFM analysis at the beginning of every project. Our engineering team will review your part design to optimize it for manufacturability, suggesting improvements for moldability, cost-efficiency, and part performance.

A: Lead times vary depending on the mold's complexity and size. For a standard cold fan or home appliance mold, the typical lead time ranges from 4 to 8 weeks. We will provide a detailed project timeline with a specific completion date after reviewing your technical requirements.

A: Of course. We always produce and provide initial sample parts (T1) from the new mold for your approval. This allows you to verify dimensions, appearance, and function before we proceed to mass production.

A: Our molds are designed to process various common plastics used in appliances, including ABS, PP, PS, PC, and PA (Nylon). We select the appropriate mold steel and design the mold structure based on your specific material choice.

A: We offer comprehensive after-sales support. This includes providing detailed mold maintenance guidelines and offering repair and modification services to ensure your mold maintains peak performance and a long service life, maximizing your return on investment.

A: Our key differentiator is our dual specialization. We are not just general mold makers; we have deep, specific expertise in both the highly technical Cold Fan category and the broad Home Appliance market. This focus allows us to provide superior engineering solutions and value for our clients in these sectors.

A: We take IP protection extremely seriously. We are willing to sign a strict Non-Disclosure Agreement (NDA) before any project discussion. All your designs, drawings, and data are treated with the utmost confidentiality and are never shared with any third party.

Standard Process for Ordering Injection Molds:

| Phase | Stage | Key Activities / Deliverables | Responsible Party | Purpose & Notes |

|---|---|---|---|---|

| Phase 1: Project Initiation & Feasibility | 1. RFQ (Request for Quotation) | • Provide detailed product design (3D CAD, 2D drawings). • Specify requirements: material, annual volume, target part cost, lead time. | Customer | Establishes the project baseline and allows the mold supplier to provide an accurate quotation. |

| 2. Design for Manufacturability (DFM) Review | • Mold supplier analyzes the product design for moldability. • Provides DFM report with suggestions on draft angles, wall thickness, gate locations, shrinkage, etc. | Mold Supplier (with Customer approval) | Critical for avoiding costly mold modifications later. Ensures the part is optimized for injection molding. | |

| 3. Quotation & Commercial Agreement | • Submit a detailed quotation covering mold cost, payment terms, and project timeline. • Negotiate and sign a purchase order (PO) and/or contract. | Mold Supplier & Customer | Formalizes the commercial agreement and project scope. | |

| Phase 2: Engineering & Design | 4. Mold Design Finalization | • Create detailed mold flow analysis. • Finalize mold design (2D layout, 3D model) including: cavity/core, slider/lifter mechanisms, cooling system, ejection system. • Customer approves final mold design. | Mold Supplier (with Customer approval) | The mold design is the blueprint for manufacturing. Approval at this stage is crucial. |

| 5. Material & Component Sourcing | • Procure approved mold base, steel (e.g., P20, H13, Stainless for corrosive materials), and standard components (hot runners, ejector pins, etc.). | Mold Supplier | Using quality materials is essential for mold life and performance, especially for high-volume家电 (home appliances). | |

| Phase 3: Mold Manufacturing | 6. Machining & Fabrication | • CNC machining of cavity and core. • EDM, wire cutting, grinding, and polishing. • Fabrication of all mold components. | Mold Supplier | The physical creation of the mold. Regular progress updates (e.g., photos) are often provided. |

| 7. Fitting & Assembly | • Assemble all machined components into the mold base. • Check for proper fit and function of all moving parts (sliders, lifters, ejection). | Mold Supplier | Ensures the mechanical integrity of the mold before the first trial. | |

| Phase 4: Sampling & Validation | 8. T1 (First Trial) & Initial Sample Report (ISIR) | • Conduct the first mold trial on an injection molding machine. • Measure and inspect T1 samples. • Provide a detailed T1 trial report with samples, pictures, and data (dimensions, short shots, etc.). | Mold Supplier | The first physical verification of the mold's performance. Identifies initial issues. |

| 9. Sample Evaluation & Engineering Changes | • Customer evaluates T1 samples for dimensions, appearance, and function. • Provide formal feedback for any required mold modifications (ECN - Engineering Change Notice). | Customer | Customer's turn to validate the part against their design and quality standards. | |

| 10. Mold Modification & Further Trials (T2, T3...) | • Implement approved ECNs. • Conduct subsequent trials (T2, T3) until samples meet all approval criteria. • Submit PPAP (Production Part Approval Process) samples if required. | Mold Supplier (with Customer feedback) | Iterative process to refine the mold until it produces acceptable parts. | |

| Phase 5: Final Approval & Delivery | 11. Final Sample Approval | • Customer issues a formal Sample Approval Sheet or sign-off. | Customer | Official confirmation that the mold produces parts to specification. |

| 12. Mold Finish & Documentation | • Apply final surface finishes (e.g., texture, polish). • Prepare and deliver final documentation: mold design drawings, maintenance manual, mold certificate. | Mold Supplier | Prepares the mold for production and provides necessary documentation for its future maintenance. | |

| 13. Shipment & Delivery | • Arrange secure packaging and shipment of the approved mold to the production facility. • Settle final payment as per the agreement. | Mold Supplier & Customer | Transfer of ownership and physical asset. | |

| Phase 6: Post-Delivery Support | 14. Production Support & Warranty | • Provide technical support during production ramp-up. • Honor the agreed warranty period for workmanship and materials. | Mold Supplier | Ensures a smooth transition to mass production and protects the customer's investment. |